My lawnmower is a late 70s Klippo with a Briggs and Stratton 4 HP engine. The lawnmower was my mothers but she switched to a new electric lawnmower. I’ve been trying to get to old Klippo to run for some time now. Sometimes the lawnmower starts then dies, but other times it doesn’t start at all. This article might help you diagnose your lawn mower problem.

Do you get spark?

Most people will change the plug or clean the plug and that’s something to try. If your machine starts and dies it most likely isn’t the issue. If you don’t have a spare spark plug you can still figure out if the one you have works or not.

Take out the spark plug with a socket wrench. If you have a spark tester use it if not then you can still test without one. Plug the spark plug into the plug boot. It might be a good idea to turn off the lights and try to start the engine. If you see sparks the plug works and the cable works. If you don’t see sparks it might not be dark enough. Try with a different spark plug.

It could be the plug boot. It could be a connection issue with the boot or a connection issue on the other end of the cable. You might have to replace the boot or the entire cable. This wasn’t my issue I had spark. It could also be the coil, but that appears to be rare.

Do you have oil?

Check the oil. Clean the oil stick and reinsert and remove and see how far up it comes. If the oil is very dark it might be a good idea to change the oil.

Dirty carburetor or dirty fuel

Dirt in the fuel or stale fuel and in the carburetor is a very common issue. You might also have water in the carburetor.

Cleaning the carburetor

Tools you need

- Screwdriver

- 13mm wrench

- 11mm wrench

- Carburetor cleaner

- Some clean rags

- Safety glasses for eye protection

Start by unplugging the spark plug boot then remove the air filter with a screwdriver. Check the air filter. If it’s really dirty replace it. If the air filter is wet with water, oil, or fuel it won’t work correctly. Replace it. If you have water in the air filter you can leave it out to dry. I don’t think you can get oil out of it.

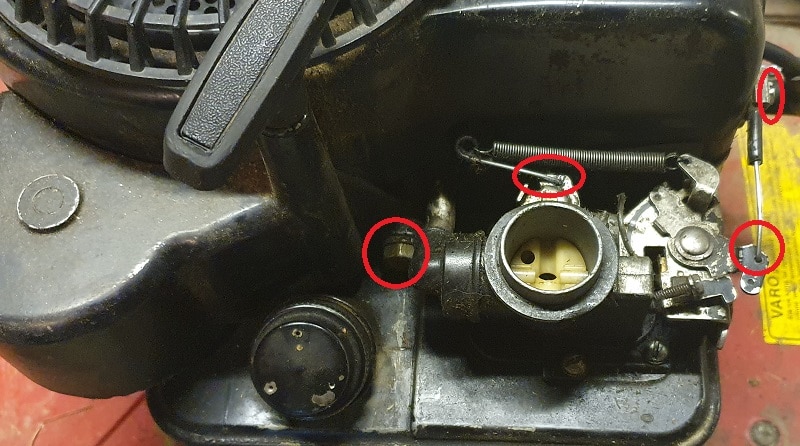

Remove the cable attached to the throttle (right side of the picture above).

Next remove the two bolts holding the fuel tank. One on the right side and one on the left. The one on the left has a spacer on many of the Briggs and Stratton models catch that one. Mine didn’t have a spacer. Once the bolts are removed wiggle the fuel tank out and tilt it to remove the remaining throttle linkage.

Now dump the fuel into a container of some kind. If it’s not clear you might have had stale fuel. Mine was clear but had some dirt in it.

Unscrew the carburetor

Now clean the carburetor with carb cleaner and a rag. Take special care with the screens at the end of the tubes. Use a screwdriver and the rag to get into every nook. Check inside the fuel tank. Spray carb cleaner there as well and if you still see dirt floating around add some fuel and shake it a bit and dump it.

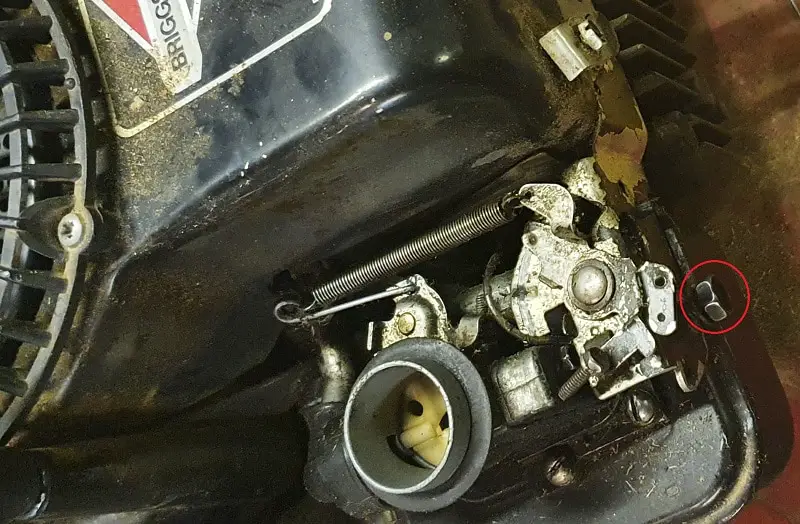

To remove the diaphragm you also need to remove a small cover on the side under which is a small linkage controlling the choke.

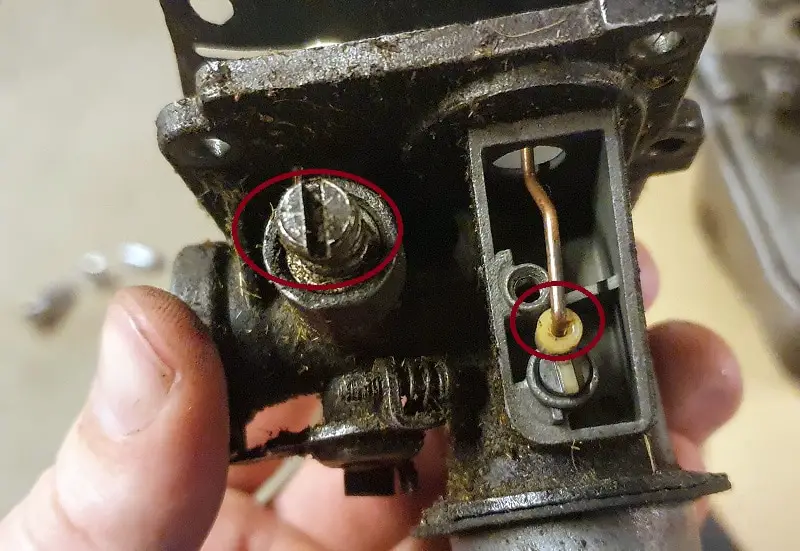

Unscrew the screw controlling idle speed and clean that also with carb cleaner. When you re-attach screw it all the way in and a few rotations back open. You will need to adjust this later if the engine still doesn’t start or runs too low or too high. To adjust this later you don’t need to remove anything it can be adjusted with everything assembled.

If the diaphragm is in bad shape or ripped you will need to replace it. Mine looked fine and I reused it.

Clean everything liberally with carb cleaner and a rag. Leave out to dry for a while. Finally rebuild everything. Take special care to place the diaphragm correctly. If it leaks air the engine might not start or runs badly.

You can try to start the engine with the air filter off. Place your hand or a clean cloth to fully or partially cover the hole the air filter covers. It won’t usually start with it totally open. If the engine starts or is close to starting then things are quite good. Put the air filter on. Try again. If it’s starts revs up high and dies then put the adjust throttle down by 10-20% try again. If it’s runs adjust the idle speed screw to find a sweet spot. Mine was runnin way too high with full throttle and wouldn’t even start. With half throttle it was about right. By fiddinling with the idle speed screw and stopper screw for the throttle I eventually found a good setup.

Some extras

When I re-assembled the carburetor and tried to re-attach it the mower it wouldn’t go in deep enough. I had to remove the cower of the mower and discovered a lot of dirt and the issue. The pipe pictured below had moved out a bit and fallen out of the hole it’s supposed to go into. Also, everything was very dirty. I used an air compressor to clean everything. I placed a clean rag to prevent dirt mixing with the oil.